INDUSTRIAL FURNACE DIVISION

MESH BELT TYPE

CARBURIZING(QT)

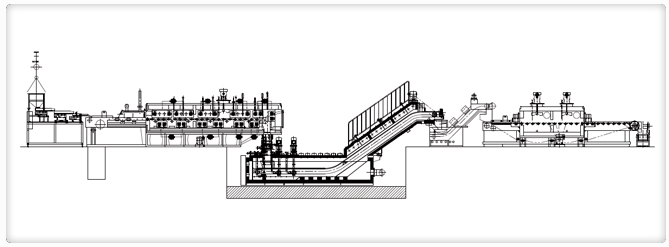

본 설비는 제품의 침탄, 조질처리 및 흑화처리를 목적으로 설계 제작된 Mesh belt식 연속 열처리 설비로서 장입부터 추출까지 모든 열처리 공정이 자동으로 수행됩니다.

공급장치, 전세정기, 소입로, 유조, 중간세정기, 소려로, 배출장치로 구성되어 있으며, 처리품으로는 자동차용 볼트, 베어링 내,외륜을 주로 처리하고 있습니다. 사용의 용이함과 품질의 균일성으로 국내외의 열처리 업체에서 많이 사용하고 있습니다.

CARBURIZING(QT)

Continuous heat-treating mesh belt furnace consists of charging, pre-cleaning, quenching furnace, oil tank, mid-cleaning, tempering and discharging furnace.

Specialized for mass production of small items such as bolts and bearings.

Both carburizing and Q/T can be done in full automatic following the mesh belt line.

STANDARD SPECIFICATIONS OF MESH BELT CARBURIZING FURNACE TYPE

| MODEL | Effective Size of Hardening Furnace (mm) | |||||

|---|---|---|---|---|---|---|

| QUENCHING | TEMPERING | Width | Length | Height | Capacity (kg/hr) | Remarks |

| CG4P51.5 | CT5P60 | 300 | 5150 | 120 | 100 | HEIGHT 150mm POSSIBLE |

| CG5P51.5 | CT6P60 | 400 | 5150 | 120 | 200 | |

| CG6P51.5 | CT8P60 | 500 | 5150 | 120 | 300 | |

| CG7P51.5 | CT9P60 | 600 | 5150 | 120 | 400 | |

| CG7P60 | CT10P72 | 600 | 6000 | 120 | 500 | |

| CG8P60 | CT11P72 | 700 | 6000 | 120 | 600 | |

| CG10P56 | CT13P72 | 900 | 5600 | 120 | 700 | |

| CG10P70 | CT14P72 | 900 | 7000 | 120 | 1000 | |

| CG12P63 | CT15P80 | 1,050 | 6300 | 120 | 1000 | |

| CG13P87 | CT16B102 | 1,050 | 8700 | 120 | 1500 | |

FURNACE FEATURE

- Electric or Gas burner, simultaneously.

- High efficiency Gas burner

- Fully automated control

- Excellent temp uniformity by RC FAN

- Excellent temp uniformity by RC FAN

- Light carb. possible in same furnace

- Suitable for mass production

PROCESS OPTIONS

- Salt quenching, None oxy-quenching, Quenching-Tempering(QT), Light carb quenching

PRODUCTS

- Bearing, bolt, nut, chain, knuckle, clip etc.

REFERENCES TOTAL 49 FURNACES

INTERNATIONAL

- JEIL INDUSTRY(JAPAN)

- NSK (INDIA)

- PT. MORITA TJOKRO GEARINDO (INDONESIA)

- HSINGUNG INDUSTRIAL (TAIWAN)

DOMESTIC

- JINHAP INDUSTRY

- KPF (KOREA BOLT IND.)

- SUNIL DYFAS CORPORATION

AUSTEMPERING

본 설비는 제품의 austempering 처리를 목적으로 설계제작된 Mesh belt식 연속 열처리 설비로서, 장입부터 추출까지의 모든 열처리 공정이 자동으로 수행됩니다.

공급장치, 전세정기, 소입로, 솔트조, 중간세정기, 건조로, 배출장치로 구성되어 있으며, 처리품으로는 자동차용 체인 플레이트를 주로 처리하고 있습니다. 시용의 용이함과 품질의 균일성으로 국내외의 열처리 업체에서 많이 사용하고 있습니다.

AUSTEMPERING

Continuous mesh belt furnace especially designed for austempering automotive parts. Consists of charging, pre-cleaning, quenching/salt tank, mid-cleaning, drying furnace and discharging furnace. Mostly heat-treating chain plate for automotive parts.

Fully automated process following mesh belt line.

STANDARD SPECIFICATIONS OF MESH BELT CARBURIZING FURNACE

| MODEL | Effective Size of Hardening Furnace (mm) | |||||

|---|---|---|---|---|---|---|

| QUENCHING | TEMPERING | Width | Length | Height | Capacity (kg/hr) | Remarks |

| CG4P51.5 | CT5P60 | 300 | 5150 | 120 | 100 | HEIGHT 150mm POSSIBLE |

| CG5P51.5 | CT6P60 | 400 | 5150 | 120 | 200 | |

| CG6P51.5 | CT8P60 | 500 | 5150 | 120 | 300 | |

| CG7P51.5 | CT9P60 | 600 | 5150 | 120 | 400 | |

| CG7P60 | CT10P72 | 600 | 6000 | 120 | 500 | |

| CG8P60 | CT11P72 | 700 | 6000 | 120 | 600 | |

| CG10P56 | CT13P72 | 900 | 5600 | 120 | 700 | |

| CG10P70 | CT14P72 | 900 | 7000 | 120 | 1000 | |

| CG12P63 | CT15P80 | 1,050 | 6300 | 120 | 1000 | |

| CG13P87 | CT16B102 | 1,150 | 8700 | 120 | 1500 | |

FEATURE

- Electric or Gas burner, simultaneously.

- High efficiency Gas burner

- Fully automated control

- Excellent temp uniformity by RC FAN

- None oxy atmosphere by RX/DX GAS

- Light carb. possible in same furnace

- Suitable for mass production

PROCESS OPTIONS

- Austemper, martemper, quenchingtempering, salt quenching, None oxy quenching

PRODUCTS

- Bearing, bolt, nut, chain, knuckle, clip etc.

REFERENCES

- BORGW ARNER(USA)

- BORGW ARNER(CHINA)

- BORGW ARNER(KOREA)

- NSK(JAPAN)